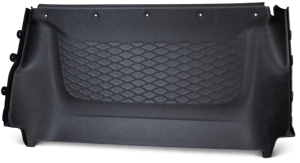

Our partitions for commercial vehicles are designed to reliably meet the high demands of the automotive industry. The components comply with both climate chamber tests according to PV 1200 and mechanical stress tests such as ISO 27965, proving their suitability for everyday use even under demanding conditions. As an ISO 9001-certified company, we rely on clear processes and modern manufacturing technology and are also able to produce a high-quality A-side with visible fabric on both sides of the component. Often, too little attention is paid to the interior of commercial vehicles, even though sound insulation, robustness and ergonomics can be ideally combined. A well-designed partition wall or rear wall cladding helps to reduce noise, enhances the appearance of the interior and at the same time offers protection against poorly secured loads.

The interior of a commercial vehicle has to withstand a lot: dirt, moisture, often rough handling of cargo. Everything is quickly thrown or stuffed into the vehicle without any particular consideration for the interior trim. In this sense, the vehicle is a consumable in the truest sense of the word. But our fleece-based composite materials are tough: the surface is hard enough to tear immediately if something hard or sharp hits it. However, the material itself is flexible enough not to break, even when it is cold outside and other plastics become brittle. The surface is abrasion-resistant but easy to clean, dries quickly and can withstand prolonged friction and impact.

Commercial vehicles, primarily delivery vans, are workhorses. After engine power, payload is the most important selling point. Cladding elements with a high dead weight are a luxury that cannot be afforded. This is precisely where our composite materials are the first choice: lightweight, stable and built for the tough working conditions of a workhorse!

A commercial vehicle is a workplace. This means that the occupants must be given special protection – including protection from the weather and noise! Condensation and the resulting waterlogging lead to fogged-up windows in cold weather, and even to frozen windows. Breathable interior trim reduces condensation and helps to quickly regulate the temperature inside the vehicle. The same applies in hot weather: a pure metal body heats up faster than a passenger compartment protected by well-designed interior trim. And you can easily measure the effect on noise yourself: compare the outside noise in the cab with the noise you hear in the uninsulated cargo area. Noise protection is health protection!

Our trim parts are designed to be easily implemented into the series production process of your vehicle. Together with your engineers, we develop the desired shape, for example the trim for a cab rear wall, and then produce it in such a way that it can usually be fitted into the cab in a single operation. Other adjacent trim parts, such as headliners and A-pillar trim, are also shaped to fit seamlessly into your workflow.

Through the targeted use of modern production approaches, such as product-neutral robot cells in conjunction with state-of-the-art software solutions, we are able to offer our customers a high level of quality and reliability. At the same time, we manage to strike the often difficult balance between batch sizes and the degree of automation. The cost-effectiveness of low to medium quantities has helped 3D composite gain a high level of market acceptance, particularly in the caravan industry.

For use in commercial vehicles, we have developed composite materials that are not only tough, but also easy to clean with water and a household cleaner. In extreme cases, they can even withstand a high-pressure cleaner – probably more so than the vehicle’s electrical system!

We are ISO 9001 certified and work with a fully digital production and quality management system. This enables us to trace every single product seamlessly: from the machine used to the material employed and the employees involved. This digital traceability system allows us to respond immediately to quality deviations, identify causes precisely and ensure consistently high process reliability.