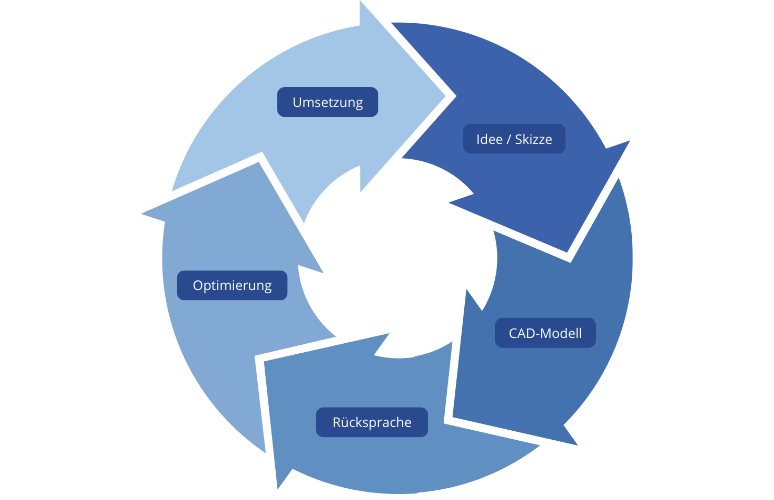

To ensure a perfect fit for our moulded parts, we work closely with our customers right from the start. Based on the product data provided, we use our own software to create precise 3D models of the required tools. All material-related properties – such as thermoelasticity, layer thickness or specific moulding parameters – are incorporated directly into the design.

The subsequent production process is equally crucial: from demoulding and cutting to the final finish, we rely on technologies that are optimally tailored to the respective material and individual workflow. We have developed many of these solutions ourselves to ensure the highest quality, process reliability and reproducibility.

The result is precise and reliable moulded parts that meet the requirements of the automotive industry as well as the needs of other demanding industries. These include applications in the agricultural sector and in the field of contract furniture, for example for high-quality acoustic panels.

Close integration between your production process and ours helps to save development time and thus costs. It also means you can be sure that your components will be exactly as you need them. Just in time!

Using our software, we create a complete digital representation of your design. This includes precise technical drawings and three-dimensional models that reveal every detail of your design. This CAD data supports your development process, increases accuracy and dimensional stability, and facilitates coordination between engineering, design and production.

The three-dimensional visualisation of your component allows us to assess its fit during installation with a high degree of accuracy. A CAD model is also indispensable for us because it allows us to optimally tailor our manufacturing technology to the specific requirements of the component. The digital data flows directly into the toolmaking process. This enables us to identify at an early stage whether adjustments to the design are necessary to ensure a smooth and efficient production process.

The finished component from our production should correspond in every detail to the model created beforehand. In addition, we provide each component with a barcode that documents the exact time of production. This allows us to immediately identify the cause of any rare deviations and remedy them in a targeted manner. Your workflow thus remains reliably protected against interruptions and disruptions.

Whether it’s a minor adjustment or a complete design, we consider function, materials and manufacturing right from the start.