Reliable mould design is the basis for high-quality thermoformed components made from PES nonwoven fabric. Right from the early development phase, we combine in-depth material knowledge with modern engineering to develop tools that deliver perfect results in series production. Our designers take into account the specific properties of PES fleece. These include compressibility, recovery behaviour and defined material compaction. We transfer all this knowledge into robust and process-reliable mould geometries.

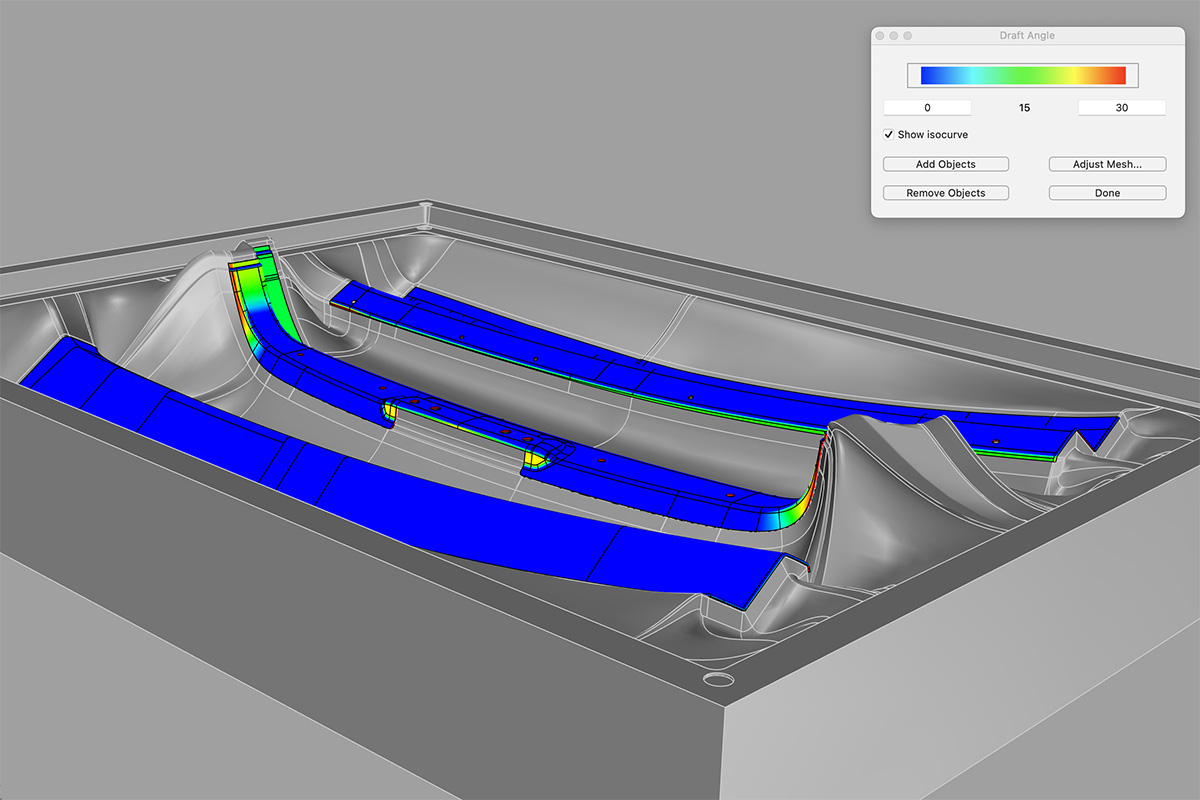

Through close cooperation with your development departments, we design tools that are precisely tailored to the installation situation and functional requirements of your component. This includes clearly defined material zones, precise contours, supports, pocket shapes and integrated functional areas. Using modern CAD systems, we simulate the moulding behaviour and optimise the tool even before the first physical sample is produced.

Our experience with tool materials and our focus on solid designs create real advantages for your projects and ensure that your requirements are implemented cost-effectively.

Your requests – including any changes you wish to make – are quickly incorporated into our production process. Working together with your technicians, we enter the desired changes into the CAD-CAM drawing of your workpiece, check the technical feasibility and quickly adapt our production to your requirements.

If you require specific moulded parts for your vehicle production, you need them promptly and not after a months-long development process. There are usually only a few weeks between your requirements and the production-ready product. And your composite moulded parts do not have to be shipped halfway around the world to reach you.

Our flexibility, geographical proximity and production process make even small series, such as those required in motorhome and caravan construction, attractively priced. And all this while maintaining the highest quality standards!

We are available to assist you at any time. At any time. Using the QR code on each product, we can determine exactly which moulded part on which machine caused a fault and when, and then rectify it immediately to minimise disruption to your workflow.

There are just five simple steps from your idea to the finished composite moulded part. First of all, we need to understand exactly WHAT you need and where it will be used. Your design language is also important, of course, because our composite moulded parts must match your end product in terms of form, function and design. Once we have understood this, we work with your engineers to develop the CAD-CAM drawing for the product. These five steps lead to your 3D composite product:

Let us work together to develop the right solution.