Nonwovens for innovations

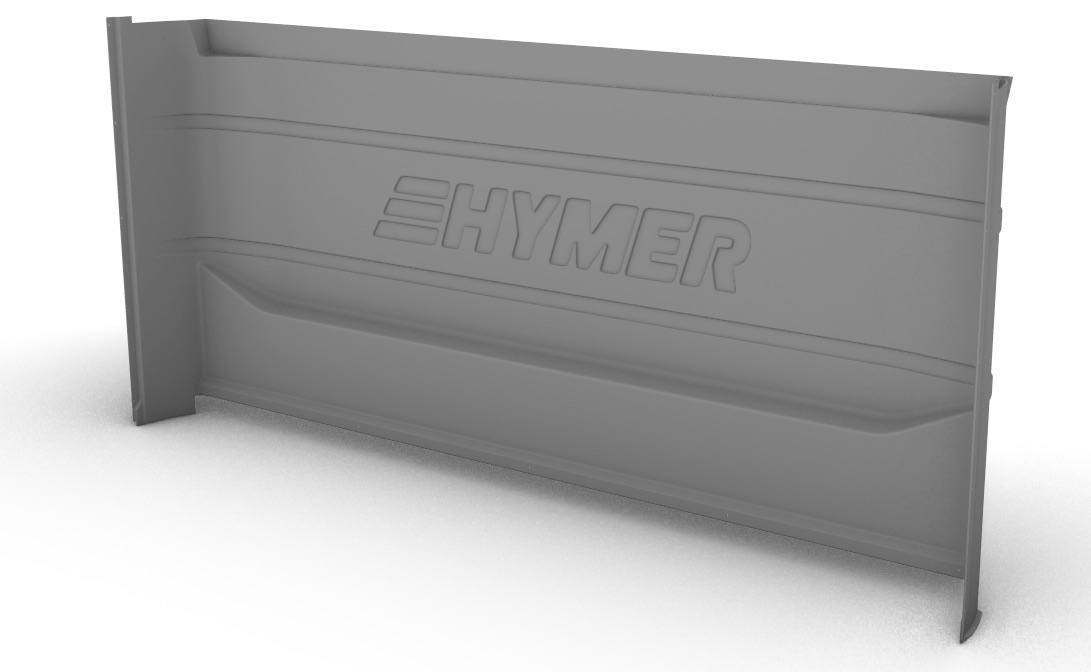

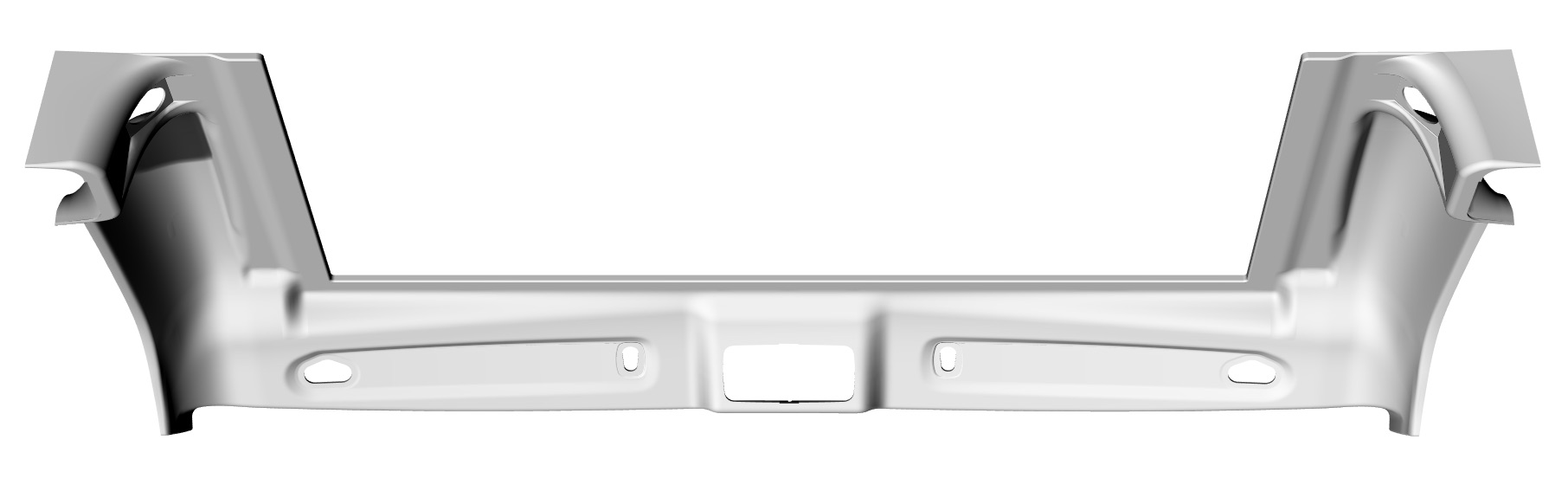

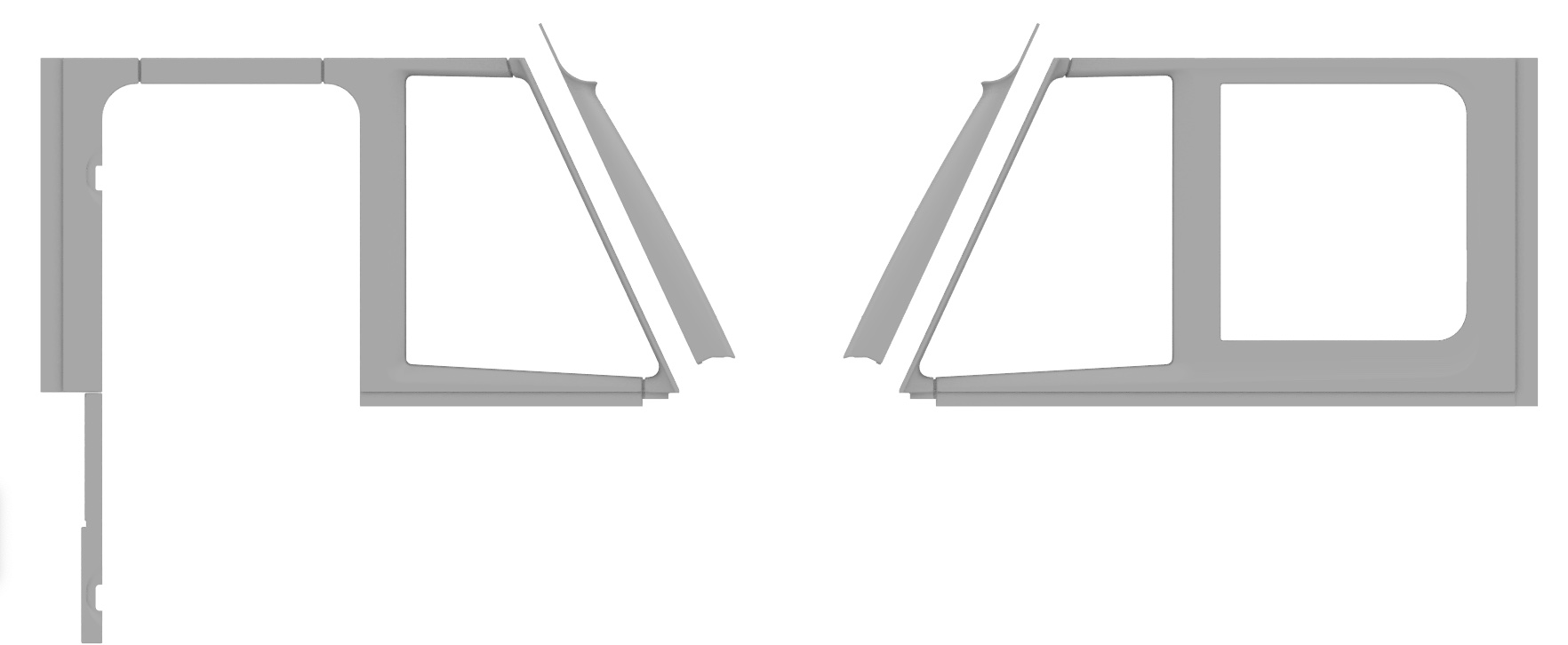

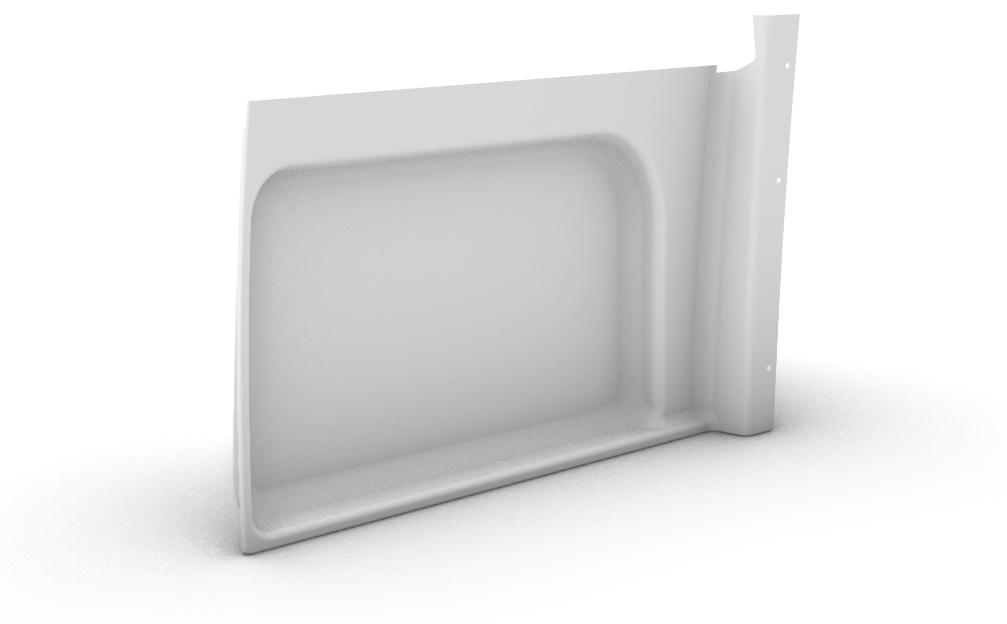

Application in the campervan - A completely new sense of space

Rear door, sliding door and pillar panels can be designed in a uniform look, although individual requests are possible at any time. Our products are the contemporary answer and are characterized by less weight, high breathability and high noise reduction.

Carrier materials

Our carrier material can be made from a variety of different fibers, such as e.g. As polypropylene, polyester, polyamide, polyethylene, acrylic or viscose exist. Renewable raw materials are also playing an increasingly important role in the field of technical nonwovens. Flax, hemp, kenaf, jute, sisal, wool and cotton are used in the field of natural fiber fleece.Polypropylen, Polyester, Polyamid, Polyethylen, Acryl oder Viskos.

product application

advantages at a glance

HAPTIC

Our products offer warm surfaces with a high quality appearance.

OPTICS

Textile molded parts create a pleasant room climate and enhance any interior while offering high deformations without material detachment or blistering. Assemblies can be replaced by large paneling parts.

ACOUSTICS

The open-pored structure of our products absorbs sound and thus promotes more pleasant acoustics.

BREATHABILITY

Moisture is absorbed and released. There is no condensation.

WEIGHT

Even with heavily deformed components, a basis weight of less than 1200g/㎡ is required

RESILIENCE

Our components withstand the high standards of the automotive industry. Regardless of whether climate chamber tests according to PV-1200 or mechanical stress tests, such as ISO 27965.